Oldtimer Motoreninstandsetzung

Präzision, Leistung und Originalität – Motorenbau auf höchstem Niveau

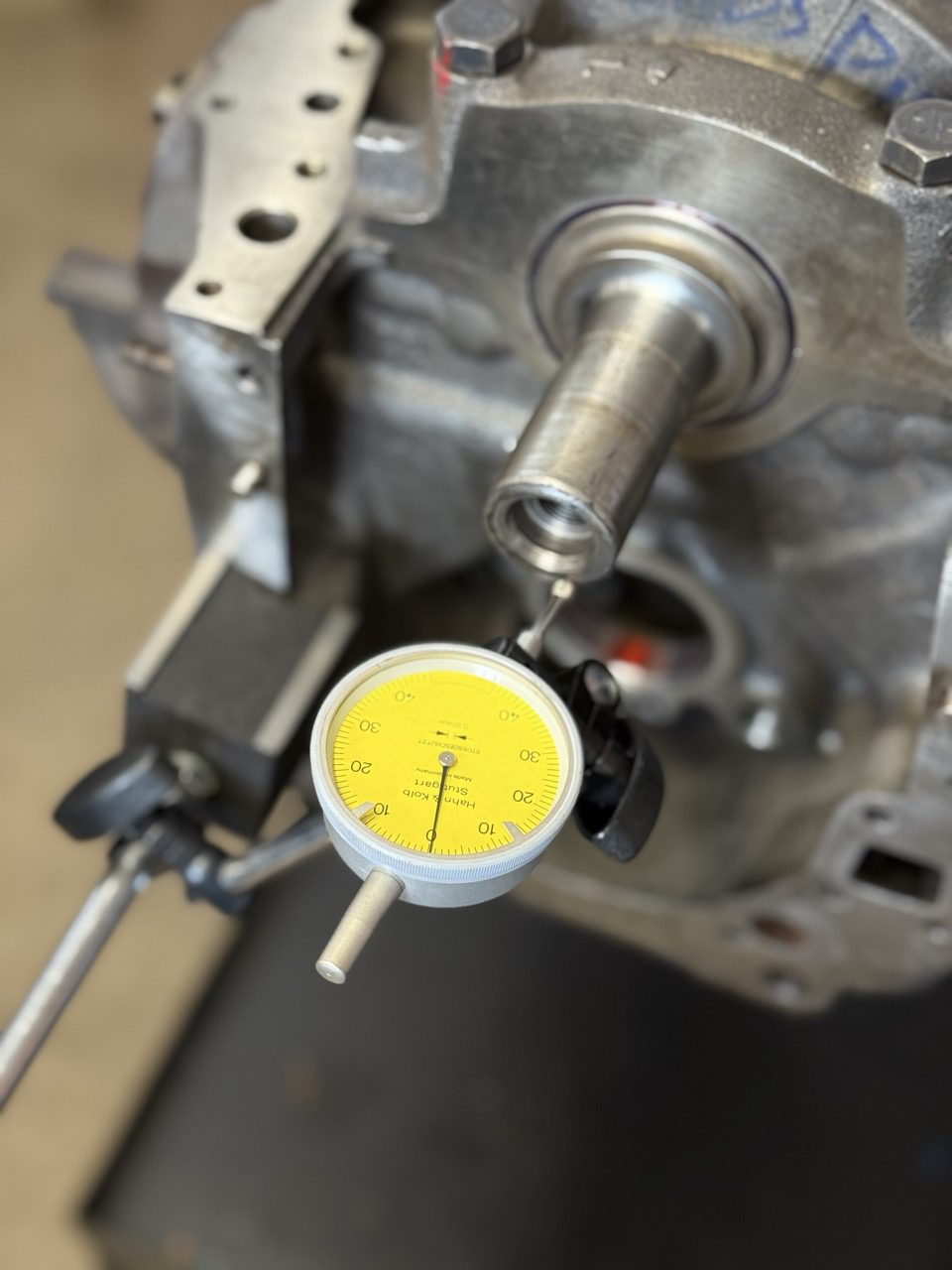

Alle Motoren aus unserem Haus werden mit höchster Präzision geschliffen, montiert und abgestimmt. Jeder Motor durchläuft unseren hauseigenen Leistungsprüfstand, wo er nicht nur eingefahren, sondern auch sorgfältig optimiert wird. So stellen wir sicher, dass Leistung, Laufverhalten und Haltbarkeit perfekt aufeinander abgestimmt sind. Auf Wunsch realisieren wir auch individuelle Tuningmaßnahmen – von einer geänderten Nockenwelle bis hin zu Hochleistungsbauteilen. Nach erfolgreichem Break-In erhalten Sie eine detaillierte Leistungs- und Drehmomentkurve, um die Performance Ihres Motors schwarz auf weiß zu dokumentieren.

Für maximale Nachvollziehbarkeit erfassen wir alle relevanten Daten in einem Engine Build Sheet. Darin sind sämtliche Maße, Toleranzen und Spezifikationen aufgeführt – ein wertvolles Dokument für spätere Anpassungen oder Wartungsarbeiten.

Auch optisch setzen wir auf Originalität: Unsere Motoren werden im authentischen Werkslack der jeweiligen US-Hersteller ausgeliefert – sei es Ford Blau, Chevrolet Orange oder Hemi Orange. So bleibt nicht nur die Technik, sondern auch das Erscheinungsbild Ihres Motors absolut zeitgetreu.

Mit einem Motor aus unserem Haus erhalten Sie ein perfekt abgestimmtes Triebwerk, das Leistung, Langlebigkeit und Originalität vereint.

Leistungsportfolio:

- Buick Nailhead Serie

- Chrysler | Mopar Small- & Big Block

- Ford 289/302/347

- Pontiac 389

- Chevrolet Small- & Big Block

Unser Equipment:

Folgende Dienstleistungen bieten wir im Hause oder zusammen mit unserem Partner an:

- Tauchbadreinigung (Ultraschall)

- Materialprüfung

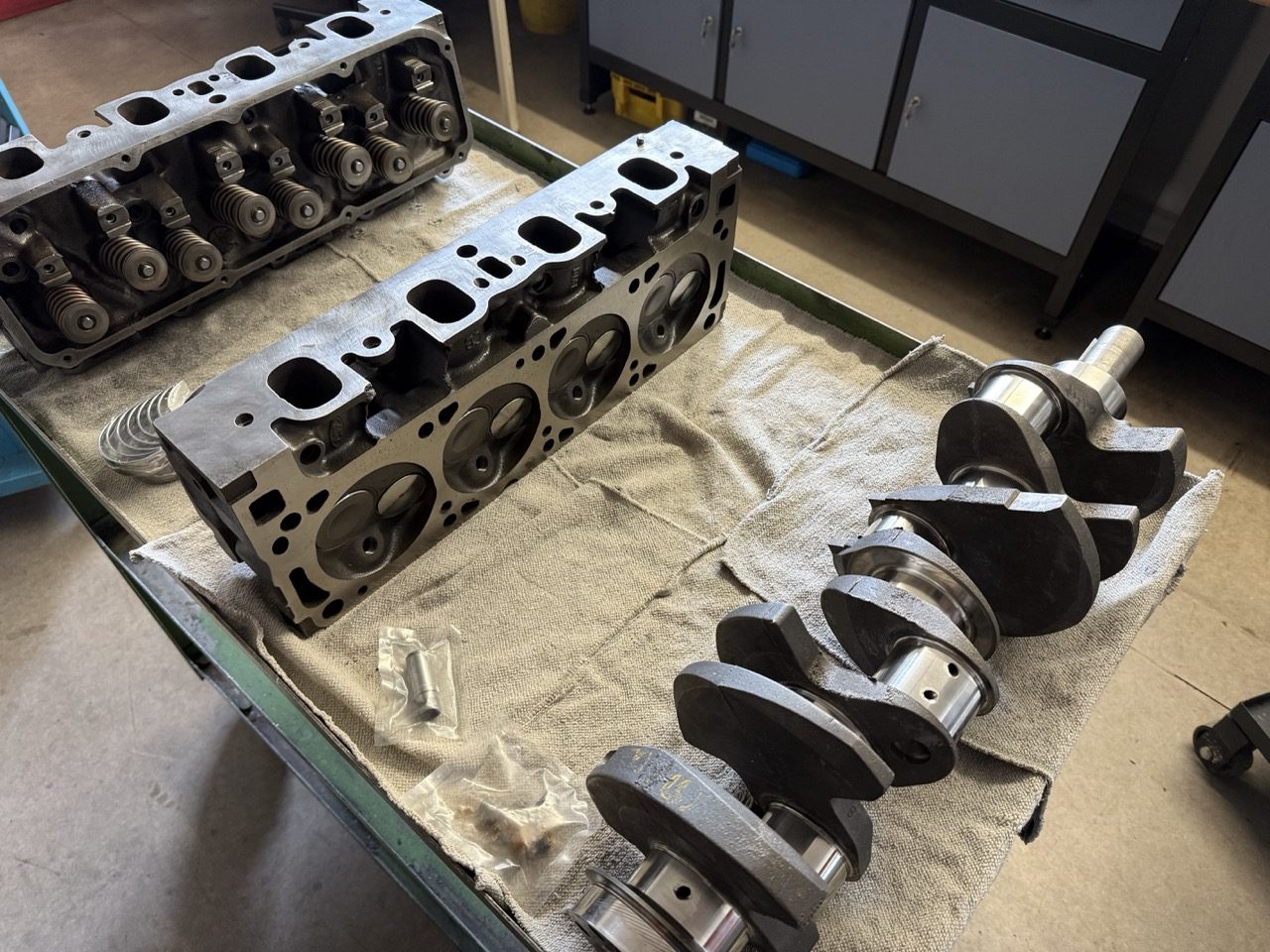

- Vermessung Zylinderblock, Kurbel- und Nockenwelle, Kolben

- Schleifen, Polieren und Nitrieren von Kurbelwellen

- Schleifen von Zylindern

- Aufarbeitung von Zylinderköpfen (Ventilführungen, Ventilsitze, Planen)

- Kolben setzen (Schrumpfsitz)

- Komplettmontage und Break-In auf dem Motorenteststand

- Abstimmungsarbeiten für Vergaseranlagen und Zündung

Ein Auszug unserer Arbeit

Buick 401 Nailhead

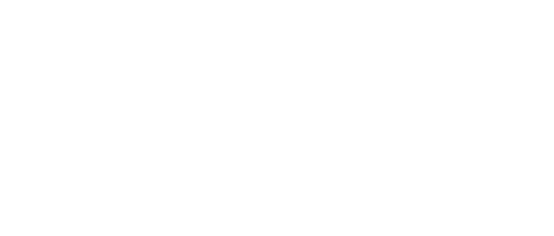

Ein Notfall, denn diesen 401 Nailhead konnten wir kurz vor dem sicheren Motorentod retten und mit viel Liebe vollumfänglich instandsetzen. Der Block wurde auf Übermaß geschliffen, die Zylinderköpfe überarbeitet, der Kurbeltrieb erneuert. Ein originalgetreuer 4bbl Umbau auf den Edelbrock AVS2 komplettiert diesen Rebuild.

Plymouth 318 Poly

Bekannt aus Chrom&Flammen, der 318cui Plymouth Poly Motor war komplett verschlissen, Froststopfen gerissen und unglaublich verkokt. Wir haben ihn nicht nur wieder komplett instandbesetzt mit Kolben nach Maß und einer extra für uns geschliffenen Nockenwelle ausgestattet, sondern auch in der Leistung gesteigert.

Pontiac 389

58 Jahre Verschleiß haben diesen Motor stark zugesetzt. Eine komplette Revision war notwendig. Kurbeltrieb, Zylinderköpfe und Anbauteile mussten vollumfänglich instandgesetzt werden. Heute ist der Block bereit für mindestens weitere 58 Jahre Service und Freude im klassischen Pontiac GrandPrix.

Chrysler 440

Der 1968er Chrysler BigBlock Motor wurde komplett überholt und mit einem originalen SixPack (3x 2bbl Vergaser) Setup komplettiert. Die Chrysler 906er Zylinderköpfe wurden komplett überholt, eine starke Comp Cams Nockenwelle und neuer Kurbeltrieb sorgen für herausragende Leistung mit Fahrdynamik.

Wir geben uns sehr viel Mühe und arbeiten mit originalen Herstellerhandbüchern, die teilweise über 100 Jahre alt sind. Oft stehen wir vor der Herausforderung gewisse Ersatzteile erst selbst fertigen zu müssen, da diese nicht mehr verfügbar sind. Eine detailgetreue Instandsetzung erfordert einen gewissen Vorlauf.

Für Anfragen haben wir eine Warteliste und besprechen gerne persönlich ein genaues zeitliches Vorgehen.

Leistungsprüfstand | Engine Dyno

Typ: Schenck D-700 mit X-act Steuerung | Prüfzelle

Mit einer Kapazität von 950PS und bis zu 3.000Nm Drehmoment können wir alle hausintern gebauten Motoren einfahren und abstimmen.

Alle unsere Motoren kommen einbaufertig, d.h. der sog. Break-In (dt. Einfahren) wurde Prüfstand durchgeführt um ein bestmögliches Ergebnis zu erzeugen. Zusätzlich kann eine Leistungsabstimmung und Optimierung erfolgen.

Für Details sprechen Sie uns an.

Häufig gestellte Fragen

Unser Portfolio umfasst folgende Motoren Typen:

- Buick Nailhead

- Chrysler Small- und Big Block

- Ford 289/302/347

- Pontiac 389

- Chevrolet Small- & Big Block

Abweichende Muster bitten wir Sie separat anzufragen. Moderne Motoren, Diesel und Yountimer sind nicht teil unseres Leistungsspektrums.

Pauschal lässt sich das nicht beantworten. Wir zerlegen den Motor vollständig, vermessen ihn und können dann die Kosten abschätzen. Oft wird im gleichen Zuge die Leistung optimiert durch z.B. Aluminium Zylinderköpfe, was sich individuell auf die Kalkulation auswirkt.

Abhängig vom Motorentyp, Zustand und Umfang der Arbeiten (Lieferzeiten Teile) kann eine Instandsetzung zwischen 3 Monaten und 2 Jahren dauern. Wichtig zu wissen, die Durchlaufzeit ist maßgeblich von der Verfügbarkeit der Teile abhängig, sowie aktueller Auslastung unserer Manufaktur.

Alle unsere Motoren durchlaufen die kritische Einfahrphase (eng. Break-In) auf dem Prüfstand im Hause. Ein Einfahren ist im Fahrzeug nicht mehr notwendig.

Alle unsere Motoren laufen mit unserem Super50 Motoröl. Da es sich meistes um Flat-Tappet-Nockenwellen handelt muss das Öl mindestens 1.200ppm ZDDP (Zink, Phosphate) enthalten.

Wir verzichten bei der Instandsetzung bewusst auf den Einsatz von Dichtmassen, wie Silikon. Wir weisen darauf hin, dass im Zuge des Motorenbau und der Revision auch alle Dichtungen erneuert werden, dennoch lassen sich unter Umständen Bauteile nicht vollständig abdichten, da die zur Verfügung stehenden Materialen und Anwendungszwecke nicht heutigen Industriestandards entsprechen. Aus diesem Grund schließen wir die Gewährleistung auf vollständige Dichtigkeit im Bereich von Kurbelwelle, Stirndeckel, Ölwanne, Ventildeckel und anderen mit Graphit- oder Kork abgedichteten Bereichen aus.

Wir liefern Motoren lackiert in der Werksfarbe mit U.S. amerikanischen Emaille Lack aus. Der Lack durchläuft während der Einfahrphase auch das sog. Einbrennen bei uns im Hause. Je nach Zustand und Alter des Blocks kann es in Kombination mit Ölen und Lösemitteln in machen Fällen dazu führen, dass dieser nicht konsistent und dauerhaft haltbar ist. Eine Verfärbung durch Abgastemperaturen ist normal (z.B. Heat-crossover bei Ansaugspinnen).

Kontaktieren Sie uns

Radspieler Classic GmbH

Hauptstraße 6

89355 Gundremmingen | Germany

Telefon: 08224 967 3790

eMail: kontakt@radspielerclassic.com